0000-00

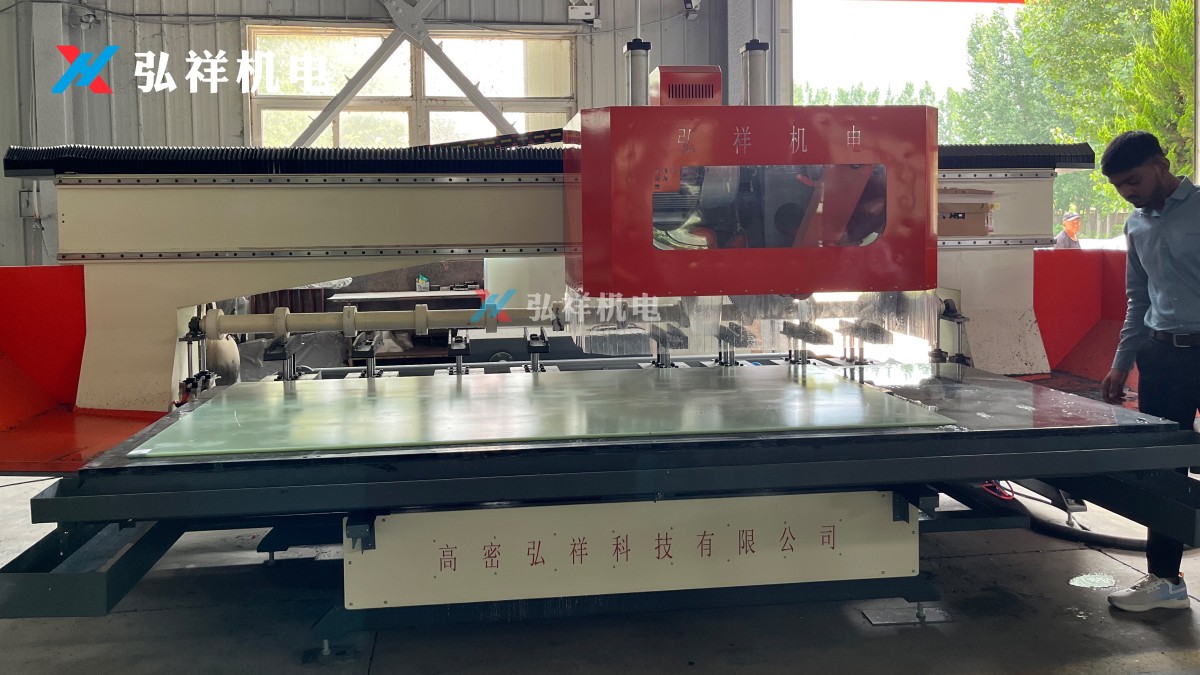

When sourcing transformer insulation parts processing equipment, choosing between custom and standard models significantly impacts your operational efficiency and ROI. This cost-benefit analysis compares CNC transformer insulation parts processing equipment for EVA molding, laminated wood, and electrical insulation applications. Discover how OEM service options from a leading Chinese manufacturer can optimize bulk orders while meeting stringent quality standards for power transformer production.

Key Considerations for Transformer Insulation Parts Processing Equipment Selection

The decision between custom and standard transformer insulation parts processing equipment requires careful evaluation of multiple technical and commercial factors. For power transformer manufacturers, the choice impacts production capacity, material utilization rates, and long-term maintenance costs. Standard models offer immediate availability and lower upfront costs, typically ranging from 15-30% less than custom solutions. However, custom CNC transformer insulation parts processing equipment provides superior precision for specialized applications like EVA molding or laminated wood components, often delivering 20-40% higher throughput for complex geometries. Technical evaluation teams should assess dimensional tolerances (typically ±0.05mm for custom CNC models versus ±0.1mm for standard), automation compatibility, and tooling changeover times when comparing options.

Operational Efficiency Comparison

Custom transformer insulation parts processing equipment designed specifically for electrical insulation applications demonstrates measurable advantages in production environments. Field data from installations in Southeast Asian transformer factories shows custom CNC systems achieve 92-95% uptime compared to 85-88% for standard models, primarily due to optimized tool paths and reduced material jamming. For bulk order processing, custom configurations with automated material handling can reduce labor requirements by 3-4 operators per shift while increasing output by 25-30%. The table below illustrates key performance metrics:

Financial Analysis: Custom vs Standard Equipment

The total cost of ownership (TCO) for transformer insulation parts processing equipment extends beyond initial purchase price. Custom solutions from reputable manufacturers in China typically command a 25-40% premium over standard models, but deliver measurable ROI through three key financial drivers: reduced scrap rates (saving $18,000-$35,000 annually for medium-volume producers), lower maintenance costs (30-45% less than standard equipment over 5 years), and extended service life (8-12 years versus 6-9 years for standard models). For OEM service providers processing laminated wood or electrical insulation components, the payback period for custom CNC equipment averages 18-24 months based on current market pricing and production volumes.

Bulk Order Economics

When sourcing transformer insulation parts processing equipment for high-volume production, custom configurations demonstrate superior scalability. Manufacturers report 30-50% faster production rates for bulk orders of EVA molding components when using purpose-built CNC systems versus adapted standard machines. The table below compares cost structures for annual production of 500,000 units:

Technical Advantages of Custom CNC Solutions

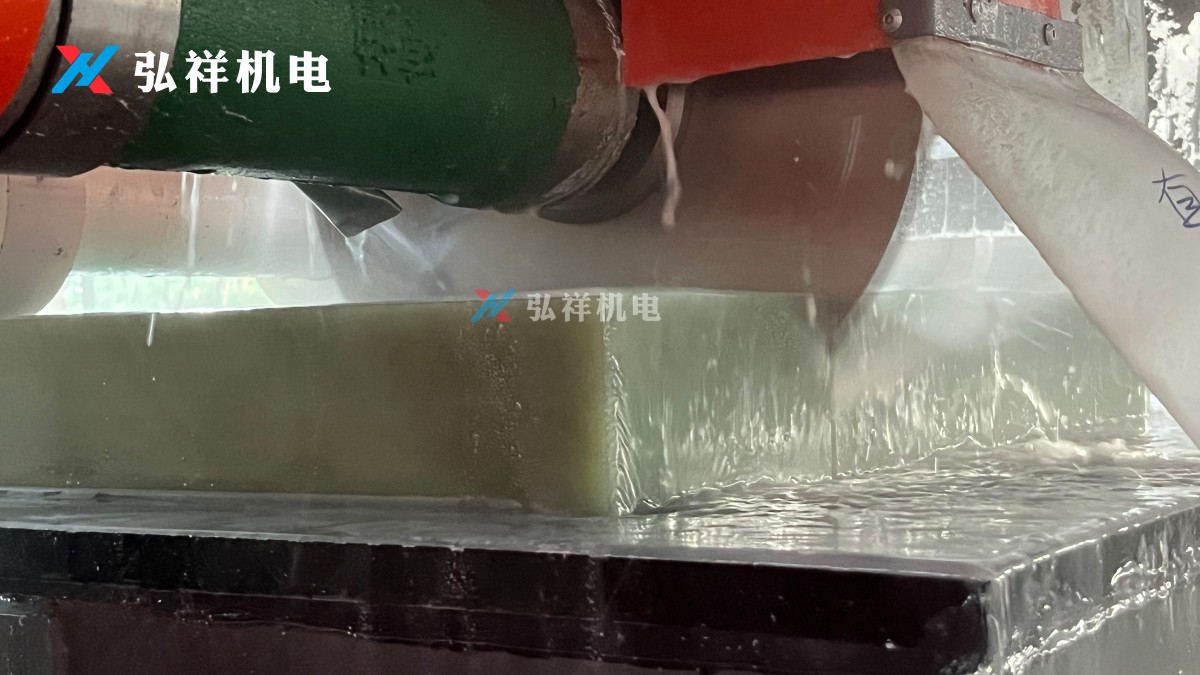

Custom transformer insulation parts processing equipment offers distinct technical benefits for specialized applications in power transformer manufacturing. Precision-engineered CNC systems achieve superior results when processing electrical insulation materials, with surface finish quality (Ra) measurements of 0.8-1.2μm compared to 1.6-2.5μm from standard machines. For laminated wood components, custom tooling configurations reduce delamination defects by 60-75% while maintaining dimensional stability within ±0.03mm across temperature variations from -40°C to 120°C. These performance characteristics are critical for high-voltage transformer applications where insulation integrity directly impacts product safety and longevity.

Quality Control Integration

Leading manufacturers in China now incorporate advanced quality monitoring systems into custom transformer insulation parts processing equipment. These systems typically include:

- Real-time thickness measurement for electrical insulation components (±0.01mm accuracy)

- Automated visual inspection for EVA molding defects (99.2% detection rate)

- Force monitoring during laminated wood processing to prevent fiber damage

- Integrated data logging for traceability and process optimization

Strategic Sourcing Considerations

When evaluating transformer insulation parts processing equipment manufacturers in China, procurement teams should assess several critical factors beyond basic specifications. For OEM service partnerships, verify the supplier's experience with international standards including IEC 60076 for power transformers and ASTM D709 for laminated materials. Technical evaluation should include factory acceptance testing protocols, with particular attention to:

- Machine rigidity and vibration characteristics during EVA molding operations

- Tool life expectancy for electrical insulation material processing

- Energy efficiency certifications and compliance with international regulations

After-sales support structure and spare parts availability

Case Study: Large-Scale Implementation

A recent project with a South American power transformer manufacturer demonstrates the advantages of custom CNC transformer insulation parts processing equipment. By replacing six standard machines with three custom-configured systems for laminated wood and electrical insulation components, the manufacturer achieved:

- 42% increase in daily production capacity

- 28% reduction in energy consumption per unit

- 60% decrease in quality-related rework

- Full ROI within 22 months

Conclusion and Next Steps

The cost-benefit analysis clearly demonstrates that custom transformer insulation parts processing equipment delivers superior long-term value for manufacturers requiring high precision in EVA molding, laminated wood, and electrical insulation applications. While standard models may appear attractive for initial cost savings, custom CNC solutions from experienced manufacturers in China provide measurable advantages in production efficiency, quality control, and total cost of ownership.

For transformer manufacturers evaluating equipment options, we recommend:

- Conducting a detailed process analysis to identify custom configuration requirements

- Requesting factory demonstrations with your specific materials

- Evaluating total cost models over a 5-7 year timeframe

- Reviewing manufacturer certifications and reference projects

Contact our engineering team today to discuss your specific transformer insulation parts processing requirements and receive a customized cost-benefit analysis for your operation.

GEZİNME

MESAJ

Fiyat Teklifi İsteyin?