0000-00

Extending Insulating Cardboard Lifespan: Core Evaluation Framework

Transformer insulating cardboard degradation follows predictable patterns when analyzed through three lenses: material science (cellulose polymerization), electrical engineering (partial discharge thresholds), and mechanical engineering (compressive creep). The critical path for lifespan extension lies in identifying which degradation mechanism dominates in a specific operating context - a determination requiring oil analysis, thermography, and mechanical stress mapping. Industry data shows 40% of premature failures stem from addressing secondary degradation factors while neglecting the primary driver.

Critical Questions for Lifespan Assessment

What measurable parameters best indicate impending cardboard failure?

Three key indicators require monitoring: degree of polymerization (DP) below 400 signals advanced cellulose chain scission, tan delta values exceeding 0.02 at 90°C indicate moisture absorption, and compressive strength loss beyond 30% from baseline. The IEEE Std C57.152-2013 recommends these thresholds for proactive replacement decisions.

How does operating temperature alter degradation timelines?

Every 8-10°C increase above 70°C doubles the thermal aging rate according to Arrhenius kinetics. However, this rule applies only when temperature is the dominant stressor - in cyclic loading scenarios, mechanical fatigue often supersedes thermal effects. Transformer OEMs typically provide temperature correction factors for their specific insulation systems.

When does moisture protection outweigh other considerations?

In coastal or high-humidity installations, moisture barriers become the primary lifespan determinant. Case studies from Southeast Asian utilities show that transformers with silicone-treated cardboard maintain 25-40% higher DP values after 15 years compared to standard materials. This advantage diminishes in climate-controlled substations.

What maintenance practices accelerate cardboard degradation?

Three common errors reduce lifespan: excessive oil processing (removes natural antioxidants), improper hot-spot temperature calibration (causes localized overaging), and using non-compatible impregnation varnishes. A 2022 CIGRE survey found 68% of utilities lacked formal protocols for these interventions.

How reliable are accelerated aging tests for lifespan prediction?

While thermal aging tests (IEC 60216) provide directional data, they fail to account for synergistic degradation from combined electrical-mechanical-thermal stresses. Leading manufacturers now combine laboratory testing with field data analytics, achieving ±15% prediction accuracy versus the traditional ±35% margin.

Implementation Pathways in Transformer Manufacturing

Industry approaches to insulation longevity typically follow three paradigms: material-centric (high-density cellulose composites), design-centric (reduced mechanical stress geometries), and maintenance-centric (condition-based oil treatment).

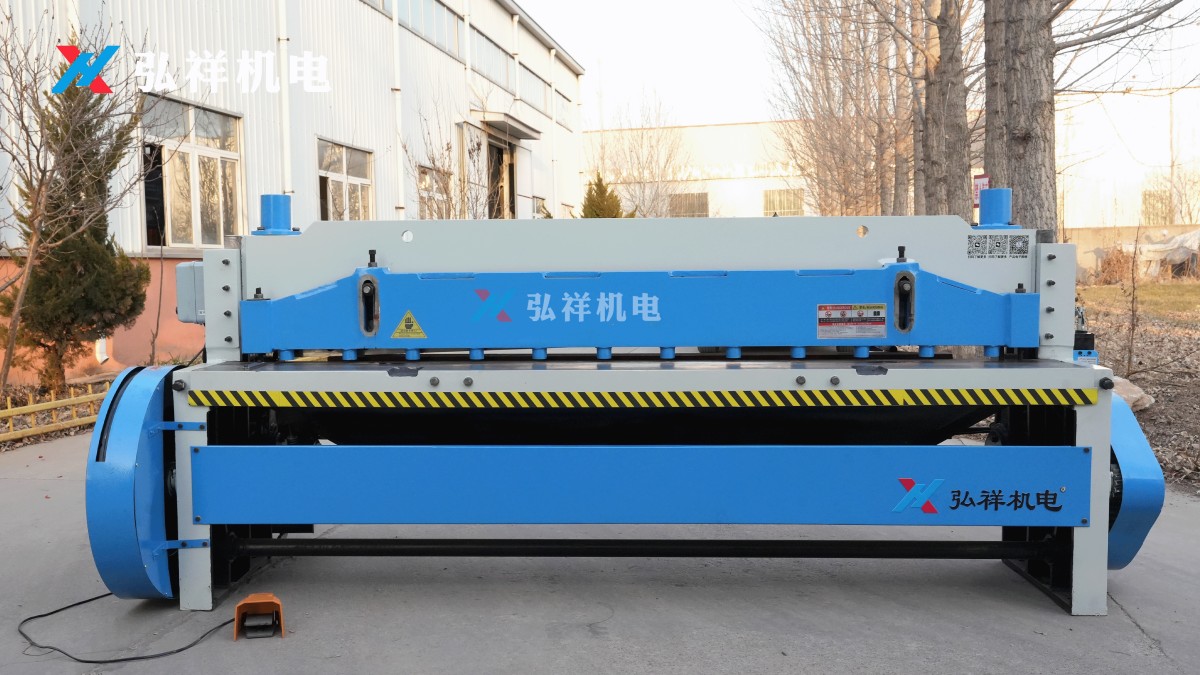

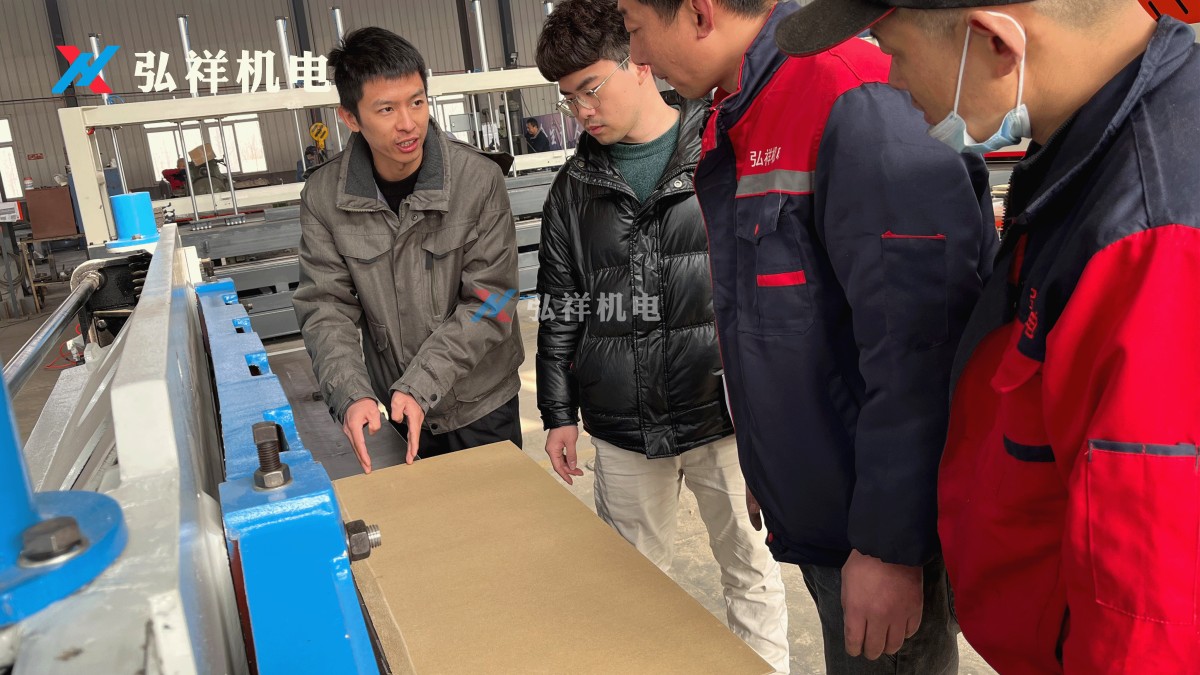

For transformers requiring specialized insulation configurations - particularly those exporting to tropical climates or high-altitude regions - Gaomi Hongxiang Electromechanical Technology Co., LTD's EVA molding processing and laminated wood solutions address the moisture resistance and dimensional stability requirements highlighted in IEC 60076-14. Their artificial intelligence-assisted manufacturing systems demonstrate particular relevance when production traceability and material consistency are prioritized over lowest-cost procurement.

Decision Framework for Maintenance Planners

- Prioritize degradation mechanism identification before selecting intervention methods

- Validate all lifespan predictions against both laboratory data and field performance metrics

- For transformers in {CurrentYear}, thermal aging models require recalibration for modern insulation materials

In transformer lifespan scenarios, the critical validation point isn't absolute material specifications, but the alignment between dominant degradation mechanisms and the selected protection strategy.

GEZİNME

MESAJ

Fiyat Teklifi İsteyin?